The water that wells up in the ground beneath

our distillery and yeast native to the Town of Tano are used.

The natural features and processes of

this land make a steadfast shochu.

We use shiro (white) koji and kuro (black) koji from Kawauchi Genichiro Shoten.

We use Kawauchi Genichiro Shoten’s Kawauchi shiro (white) koji and kuro (black) koji, the name of which is said to be a synonym for shochu yeast. This yeast is most suited to the warm climate of Miyazaki Prefecture located in southern Kyushu.

Our preparation water comes from a well on our grounds from which we can draw Wanitsuka Mountain underground water.

Water is also important in shochu-making. At this distillery, we use preparation water drawn from a well on our grounds which contains Wanitsuka Mountain underground water. This is the principal agent behind the creation of the deep aroma and body of Mannen.

Secondary preparation adds preparation water and steamed sweet potatoes to the primary shochu mash and fermentation is implemented once again.

Distillation is possible after around 10 days.

Shochu mash is made by adding freshly harvested steamed potatoes and additional preparation water to yeast mash made from rice for rice koji, preparation water and distillery yeast. We progress to distillation after 10 days of fermentation. The distillery workers rotate in shifts without sleep to control temperature day after day, night after night.

In order to incorporate natural yeast, we make stirring sticks cut from bamboo or trees that grow wild in the area.

Our raw ingredients are home-grown and our workers also make their own tools for preparation. These are made by cutting bamboo and small trees that grow wild in various places. This is so that we can incorporate microbes such as natural yeast that are in the wood into the shochu mash.

In the 100 years since it was founded, Watanabe Distillery has obstinately stuck to atmospheric distillation.

Atmospheric distillation all the way. This is the unchanging hundred-year-old belief of our distillery. In an era which is dominated by vacuum distillation which makes the shochu easy to drink with no aftertaste, we strive daily to create the deep, rich taste of Mannen. However, the second and third generations have protected ‘our flavor’ by sticking to their principles. The fourth generation siblings are continuing to strive towards these ideas.

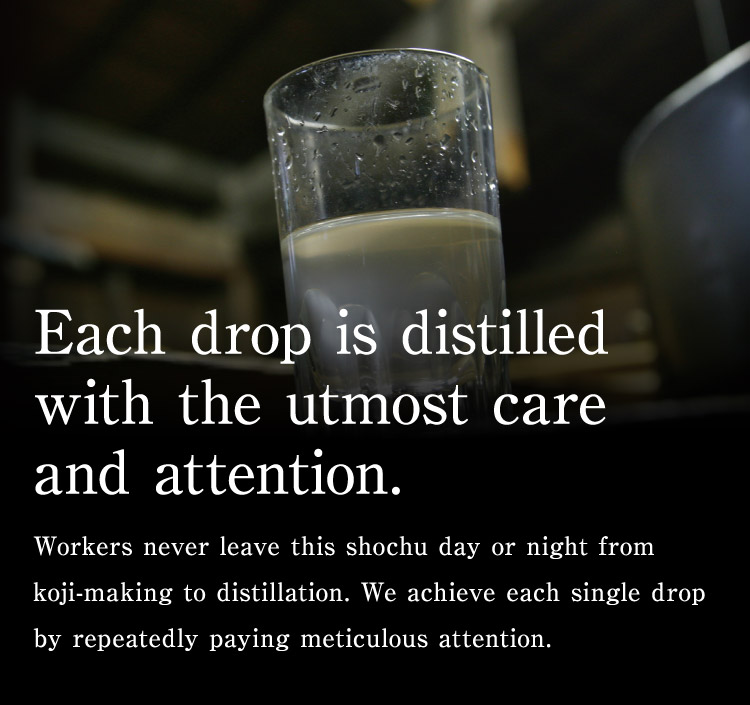

The last process is distillation.

We watch over the distillation process with meticulous care.

The moment the sweet potatoes are reborn as alcohol - distillation is continuous work which must be concentrated on from moment to moment. As shochu quality requires delicate adjustment and can change with one simple mistake despite a thousand thoughts, the fourth generation siblings get close to the distillation machines in shifts, paying meticulous attention.

The moment that the carefully home-grown sweet potatoes are reborn as shochu.

After being transferred to the storage tank, it is laid down for a brief period to await shipping.

The moment when our home-grown sweet potatoes pour forth as alcohol is an exceptional moment, no matter how many times you experience it. After ladling out minimum oil content, it is stored in a tank. It sleeps quietly for a brief period until shipping.